Group assignment2: CO2 Laser Machine

Our instructor ABDULLAH give us some information about LASER machines. There are 3 type of it CO2, YAG, and FIBER, and in this course we will use and talk about CO2 laser machine. And we can do a smaller project from our design or the big design. That make us see what are the problems that will face us or how we can complete the project easer and how the project look like. In the machine we can control the path of the laser by 2 axis x and y, z is not important one we can ignore it but the laser should be at 8 mm higher than the plate. Laser beam physics is mixture consist of CO2, N2 ,and He and there are some mirrors inside it. This machine can cut thin and soft material ,so it cant cut material like stainless steel. The cutting of the laser depend on three parameters Power of laser and speed and frequency, but it is not important. There are two type of paths cutting and engraving and If you want to do engraving or cutting, there are different settings for different material and also different thickness need different power. also, there are a different type of cutting techniques Kerfings, multilayer, digital fabrication, joints, press fit and we will use press fit today.

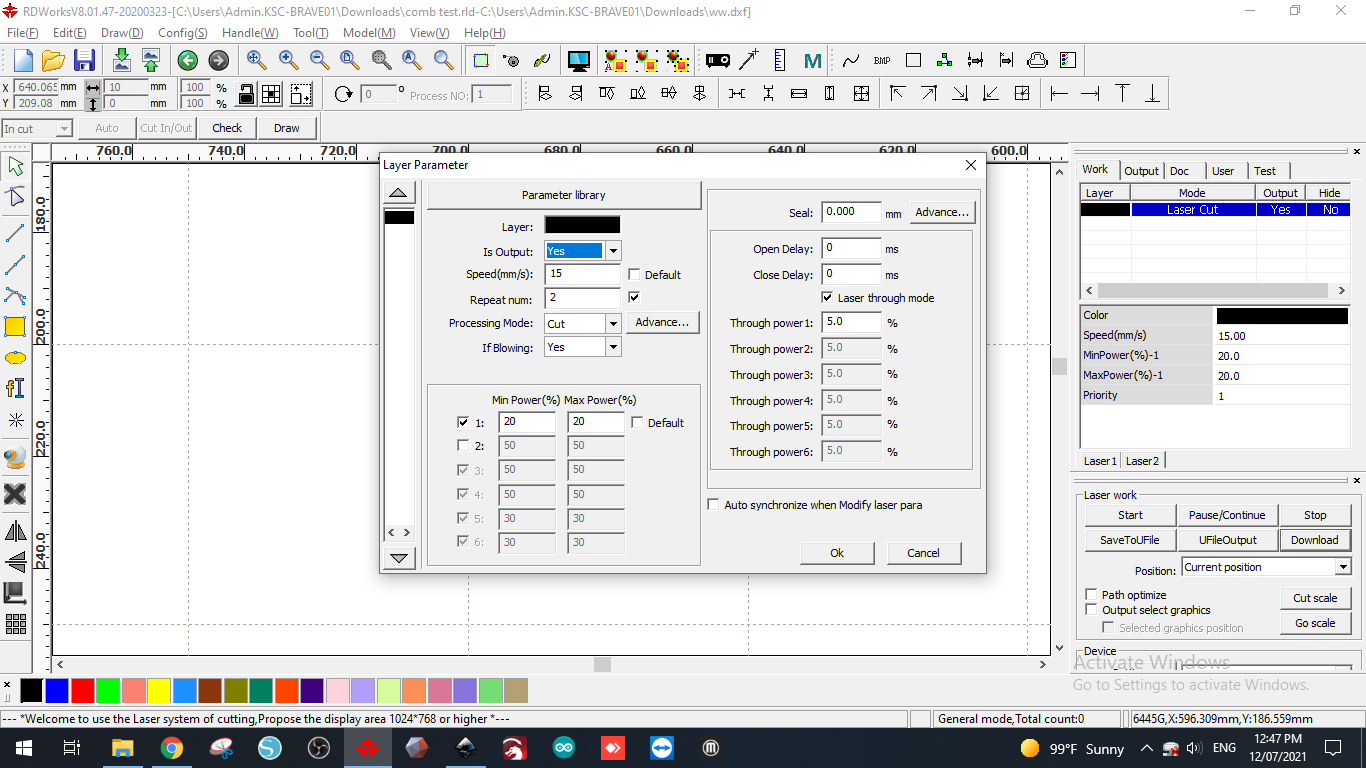

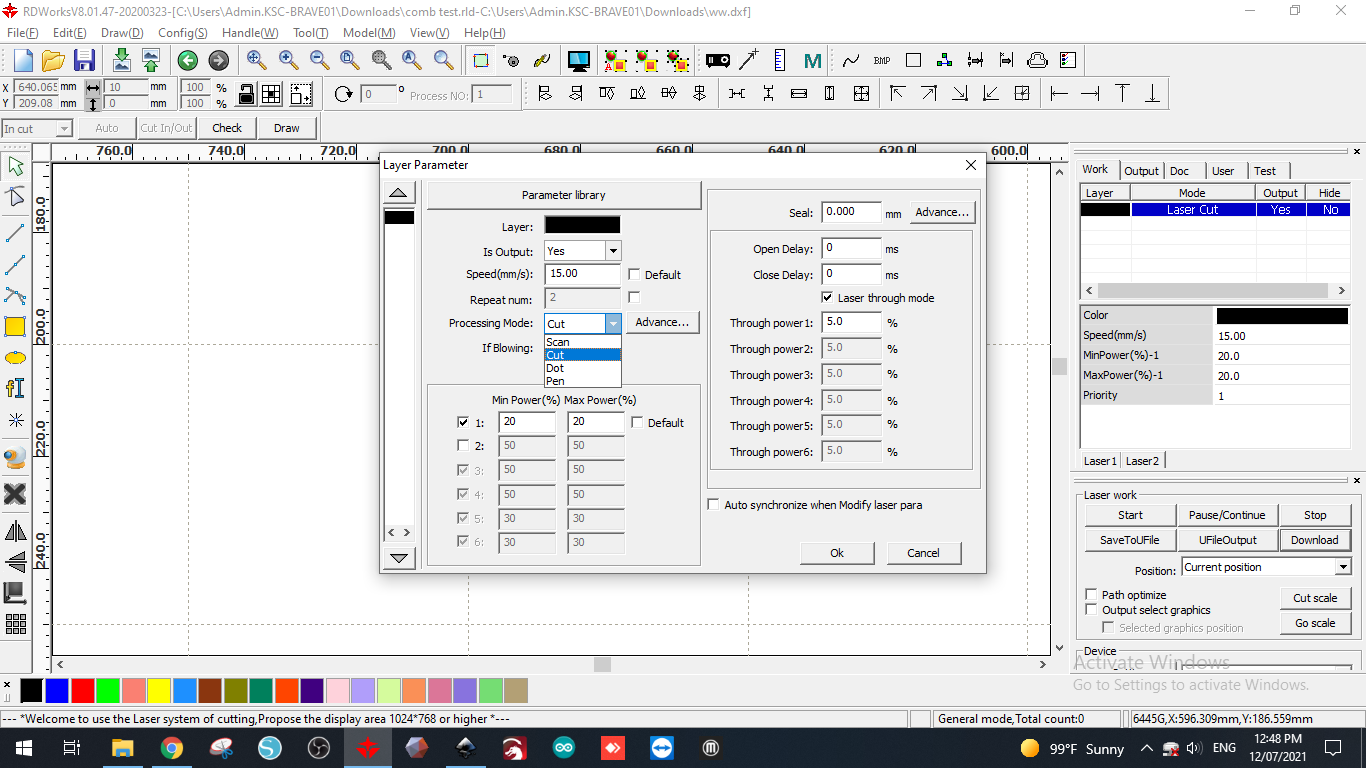

Than, we go to the machine and there is a program that we used it to control the machine we put or change the needed parameters like speed, power, and repeat number or how much number that the laser cut the same place. Try and do some test with your plate to find the needed value of the parameters to cut your 2D design without ruin the plate. And choose the appropriate speed and power because there is a relationship between them and if you increase the power and decrease the speed the plate will fire and by decreasing the speed the time needed for the cut will rise, and if you increase speed and decrease power the laser will not cut the plate clear. So we learned that there are relation shape between the two parameters and you should change them to be appropriate to the type of the plate and the thickness. After do some test we find the appropriate parameters to be

Try and do some test with your plate to find the needed value of the parameters to cut your 2D design without ruin the plate. And choose the appropriate speed and power because there is a relationship between them and if you increase the power and decrease the speed the plate will fire and by decreasing the speed the time needed for the cut will rise, and if you increase speed and decrease power the laser will not cut the plate clear. So we learned that there are relation shape between the two parameters and you should change them to be appropriate to the type of the plate and the thickness. After do some test we find the appropriate parameters to be

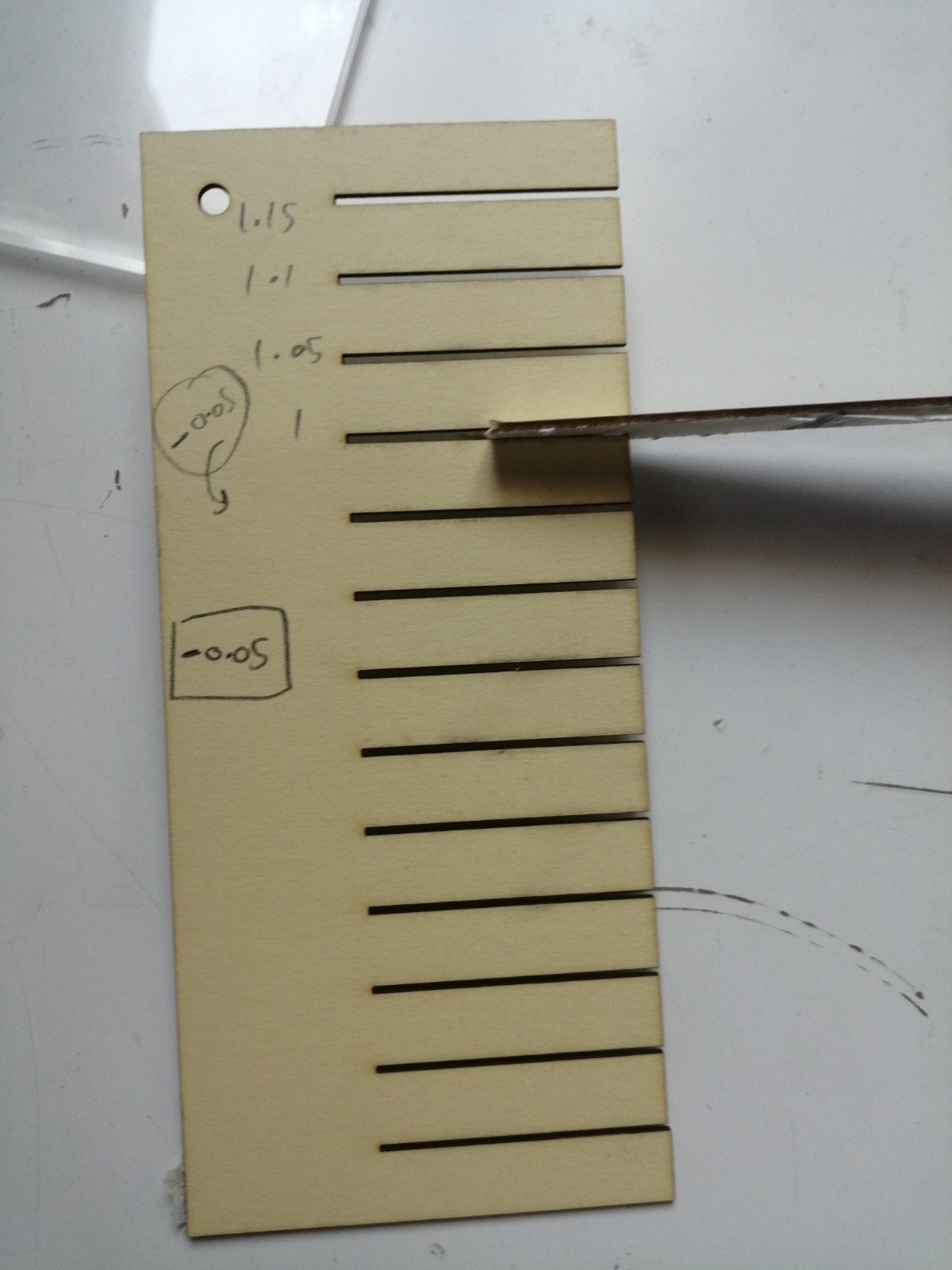

Next, we want to do fitting test to see the appropriate dimension for our design by do this skitch on the laser

Next, we want to do fitting test to see the appropriate dimension for our design by do this skitch on the laser

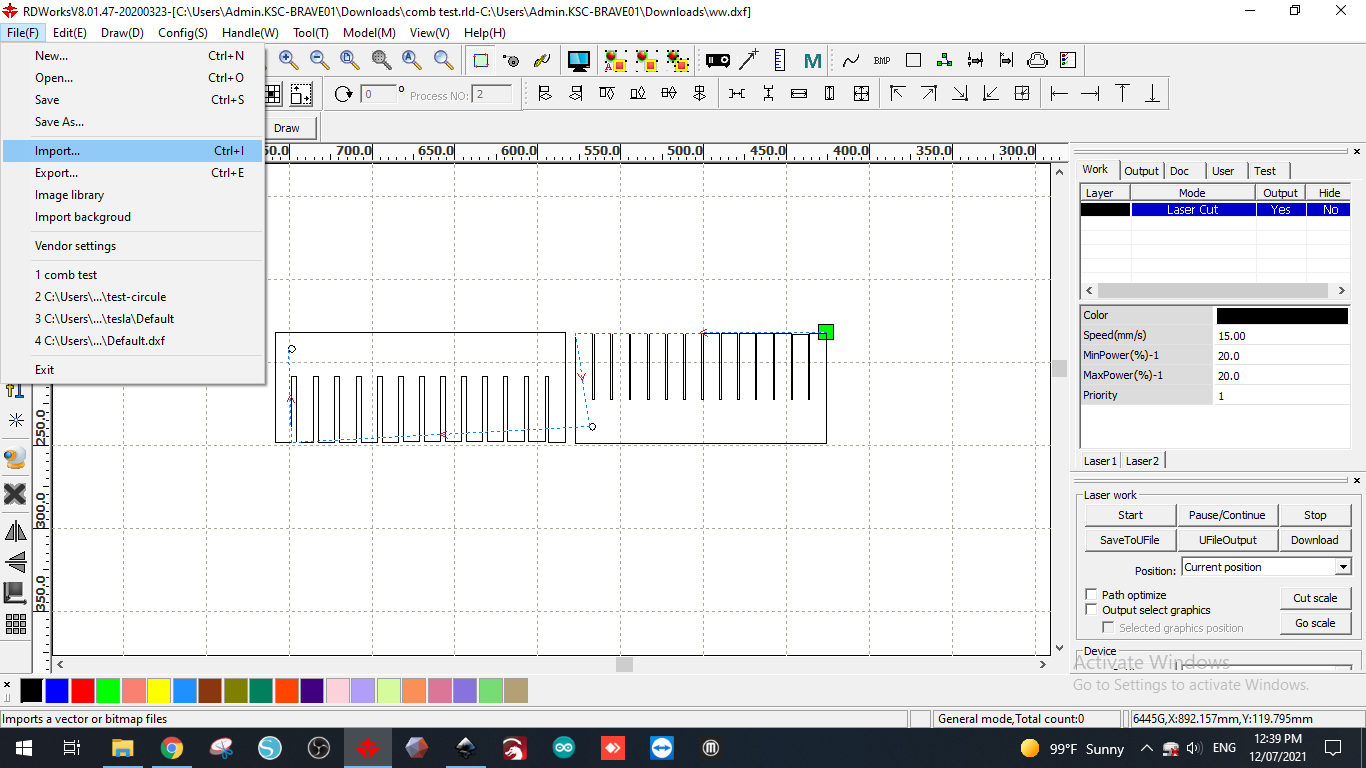

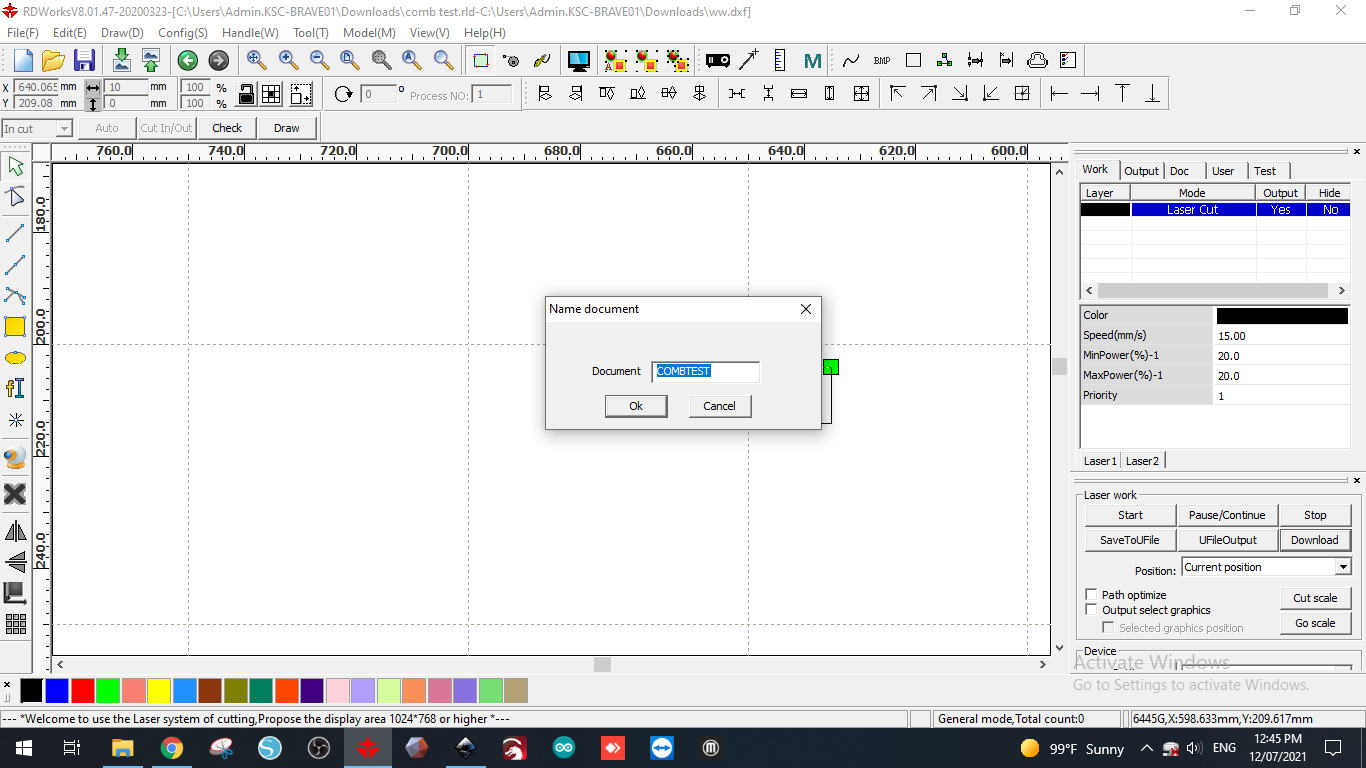

and we can see from this picture we appload the above skitch to RDWorks program as XDf file by click to file than import and save this file.

and we can see from this picture we appload the above skitch to RDWorks program as XDf file by click to file than import and save this file.

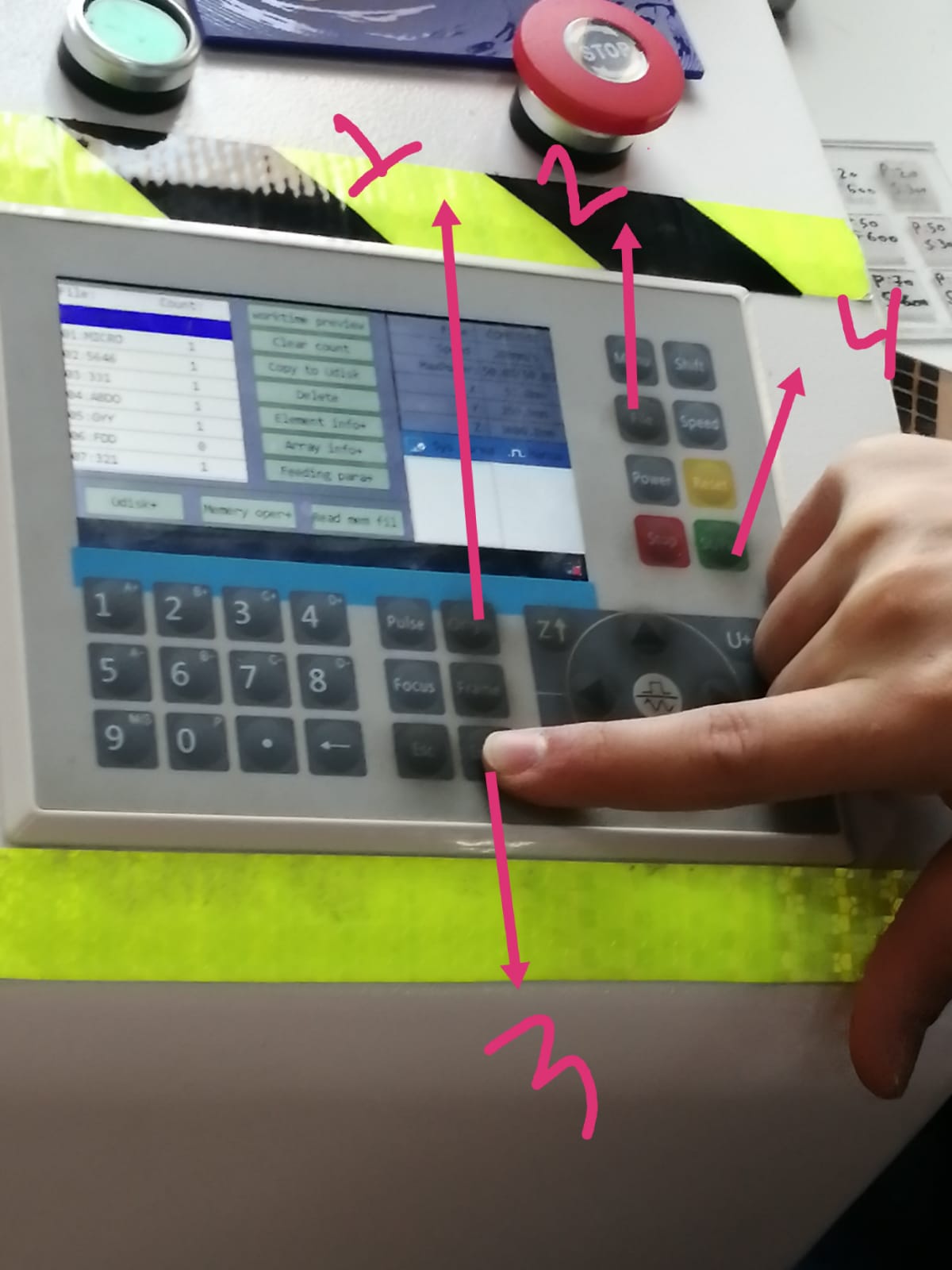

Next we go to the control board of the machine

Next we go to the control board of the machine

And we start the machine by click to origin key to make the machine back to the starting point. Second, we click to file key and choose our DXf file that we import and saved it. Third , we click to frame key. finally, we click to start key that we can see it in green color.

And we start the machine by click to origin key to make the machine back to the starting point. Second, we click to file key and choose our DXf file that we import and saved it. Third , we click to frame key. finally, we click to start key that we can see it in green color.

Than the machine will start cut t the end we got this plate

Than the machine will start cut t the end we got this plate

and from it we can find the appropriate dimension of the gab or the joints. And we can see from it the largest gap has 1.15mm and we test them and choose the 1mm gap.

and from it we can find the appropriate dimension of the gab or the joints. And we can see from it the largest gap has 1.15mm and we test them and choose the 1mm gap.

and if a problem faced you or something happened and you want to stop the machine you can stope it by using the emergency switch in the red color or by click to stop key on the board.